UMC relies on Fastenal to drive costs out of their business

Updated November 27, 2023

By Curt Trnka | Blue Print Editorial Team

By Curt Trnka | Blue Print Editorial Team

Mukilteo, Washington

|

KNOWING HOW TO GET THINGS DONE

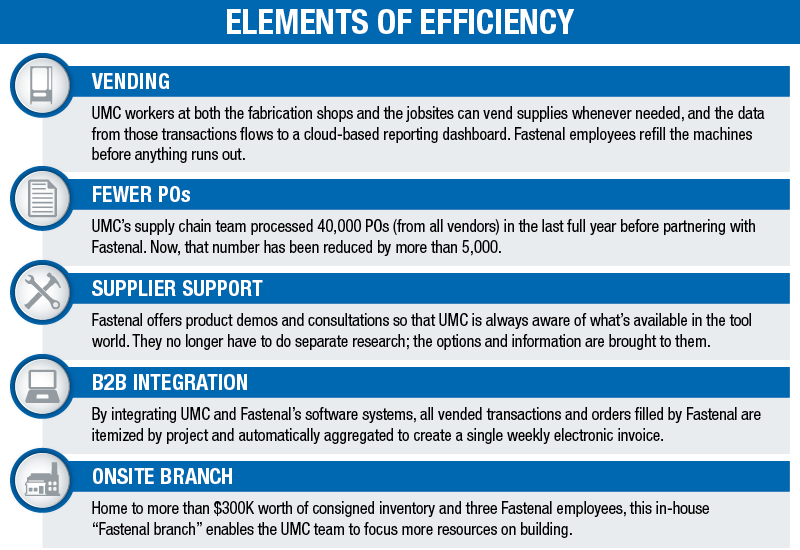

As a growing company in a fast-paced industry, you might mistake UMC for a new player, but the organization opened its doors in 1920. In that time, the company has worked on some of the most iconic buildings in Seattle, including the famed Space Needle. Today, UMC is an innovative mechanical contractor handling HVAC, plumbing, fabrication, and fitting work in high-tech facilities, such as hospitals, labs, data centers, and high-rises. They specialize in sustainable buildings that help reduce energy and operational costs for tenants throughout the Puget Sound region. And they believe creating a high-performance building that can conserve resources starts with design, continues through construction, and requires ongoing check-ins during its lifecycle. “The construction world has changed over the past couple years, and tends to get faster and faster,” said Ian Footer, UMC’s warehouse manager. “So, we always look for ways to bring innovation into it, to help with a proactive approach instead of just reacting to every situation.”

|

To reach out to a Construction Specialist, please email [email protected]

Like what you're seeing here? Subscribe to the Blue Print for FREE and get the magazine sent right to your address.

WHAT THE UMC TEAM SAYS Ian Footer I Warehouse Manager

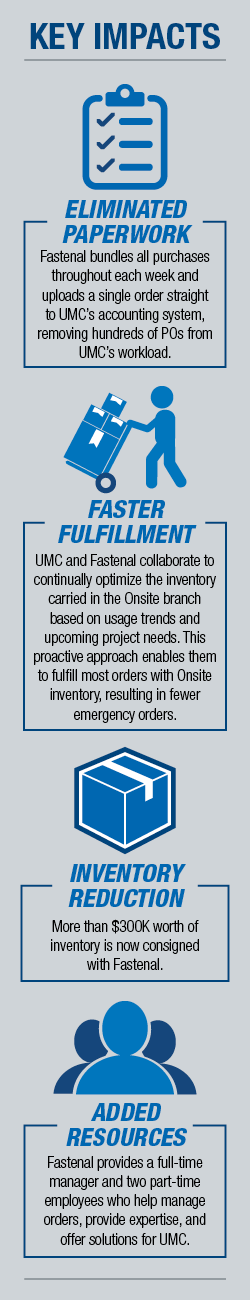

“Having the Fastenal employees out there, they bring a world of knowledge and all their vendors. So you’ll have a conversation with them and they’ll throw out, ‘Have you heard of this group?’ or ‘Have you ever heard of these guys, because they are really good at this.’ That partnership is constantly evolving back and forth. You think you’ve hit the peak and say to yourself, ‘This is all that Fastenal can do; I know everything that they handle.’ But you don’t know everything that they handle. They’re always bringing more to the table, and it’s providing a better service overall for our own employees.” Tom Donaldson I Supply Chain Manager

“I think we’ve worked well with Fastenal to make them understand the challenges of being a mechanical contractor in this market. It’s very difficult. It’s demanding. The owners and the general contractors have high expectations from us in a short time frame, and we need people who are responsive to that. Fastenal was one of those partners for us. I like the fact that there’s a mutual respect for one another, a desire to succeed, a desire to be one of the best in the industry, and be an innovator and be a pusher. I think that’s what’s driven this relationship in the right direction.” Melissa Feiler I Tool & Equipment Manager

“Fastenal really helps us with change orders. We could get an order in at 9 a.m., and by 10 o’clock Fastenal has the order picked and to our receiving department so that I can get it on a truck by noon, and get it out into the field by 1 o’clock. You just never know what they’re going to need at what time to complete a project. To have them here, on-site, to just pick it up and go: They get it done for us.” |