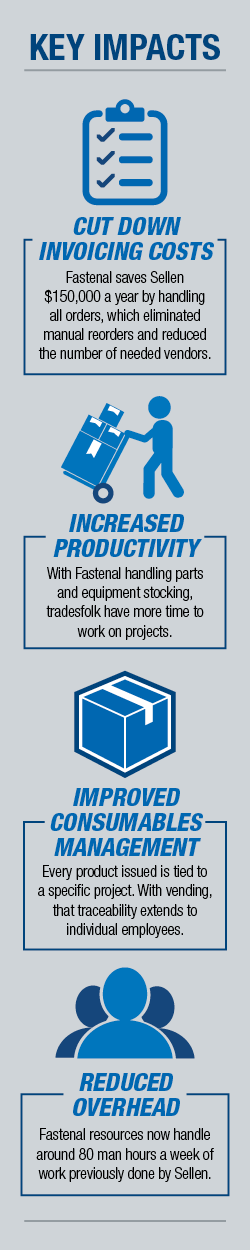

Sellen Construction cuts down on manual orders, saves $150K per year

Updated April 27, 2023

By Blue Print Editorial Team

By Blue Print Editorial Team

Seattle, Washington

|

BUILDING A BETTER SUPPLY CHAIN

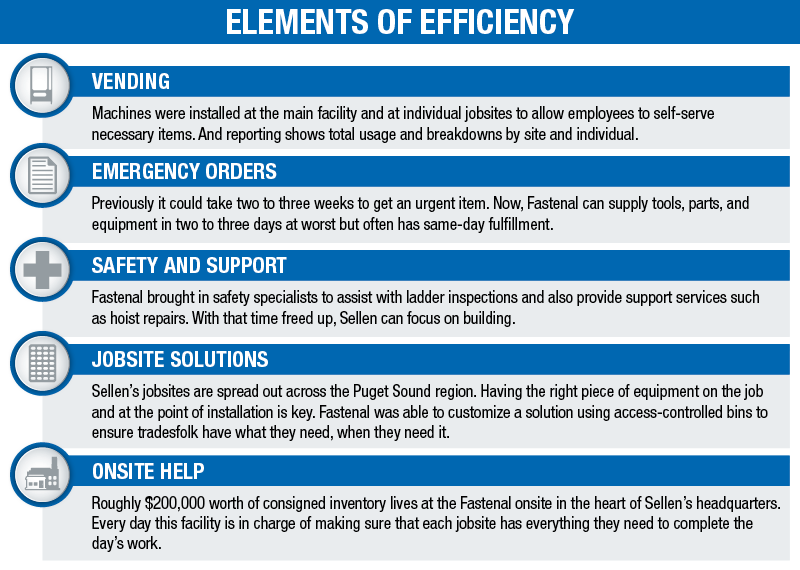

Whether it’s a new skyscraper or the renovation of a historic landmark, Sellen Construction can handle the project. Based in Seattle, the company has built some of the region’s most iconic structures, including innovative projects for world-class companies like Amazon, Microsoft, and AT&T. Sellen’s business is structured to focus their team’s energy and talent on build time – so that, ideally, every dollar spent, every ounce of effort, is poured into the project. The supply chain plays a pivotal role. Reducing delays, touches, and waste creates more time and resources for Sellen’s craftspeople to focus on what they do best: delivering projects that bring success to their partners and the community. “We decided that we needed to find a partner to help us manage our supply chain,” said Adam Rohde, Vice President, Sellen Construction. “We’ve always been a bit of a “do-it-yourselfer” type company, but we do realize that, with partnership being one of our main values, that there are other stakeholders out there who can do things better than we can do it. And that only helps us achieve our goals.”

|

Like what you're seeing here? Subscribe to the Blue Print for FREE and get the magazine sent right to your address.

WHAT THE SELLEN TEAM SAYS Adam Rohde | Vice President - Director, Operational Excellence and Engineering, Sellen Construction

“When I think about the partnership between Sellen and Fastenal, it has just taken the best parts of both companies and allowed us to take the whole idea of supply chain management within this context of the general contracting community and push it forward to a place that it’s not been before.” Travis Muld | Warehouse Business Manager, Sellen Construction

“The Onsite solution team is now part of the Sellen team. They help us get everything done that we need to do every day. They are helping us get better at supply chain management, and it’s truly value added. The support that they get from their upper management is superb. You cannot ask for anything more.” Tim Bowman | Warehouse Operations Manager, Sellen Construction

“I spent a lot of time doing emergency orders and trying to figure out which supplier to get it from the quickest so I could get it to the jobsite. When Fastenal came in it just made it more efficient. The product was there when I needed it, and I didn’t have to wait around. I didn’t have to make emergency calls.” FASTENAL'S TAKESteve Leal | District Manager, Fastenal

"Every time a product is issued to a jobsite, we track that data and not only from which jobsite but from what phase and who took it and when it went out and what type of job it was. So, what’s exciting about it is we go through the data and it’s starting to become a forecasting model of what products should we have in our Sellen Onsite branch. And what products don’t they need anymore. Then we look at some of the other jobsite services that they’re outsourcing to other folks that could be taken back in house and run through the Fastenal program, effectively yielding more time for the jobsite to focus on building.” |