Pierce Manufacturing streamlines production while keeping every build custom

Updated May 5, 2023

By Curt Trnka | Blue Print Editorial Team

By Curt Trnka | Blue Print Editorial Team

Custom units are finished and waiting at Pierce's main Wisconsin location.

|

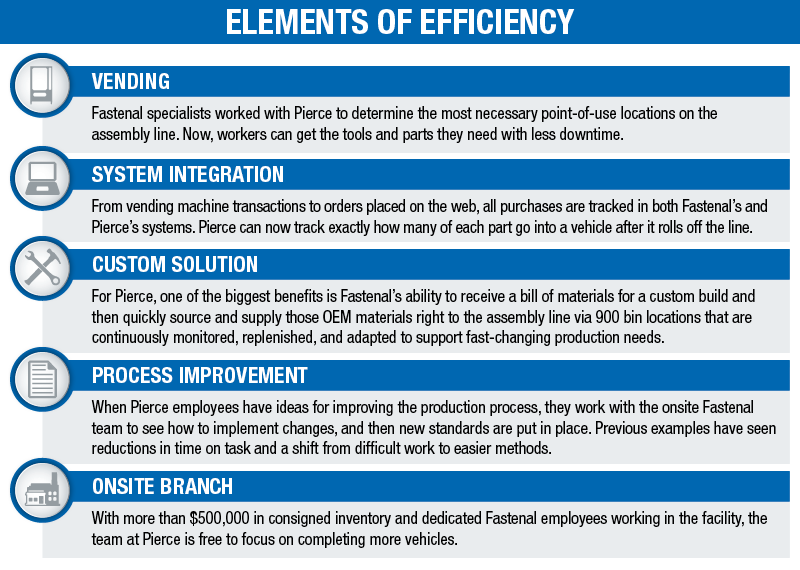

EVERY BUILD IS UNIQUE

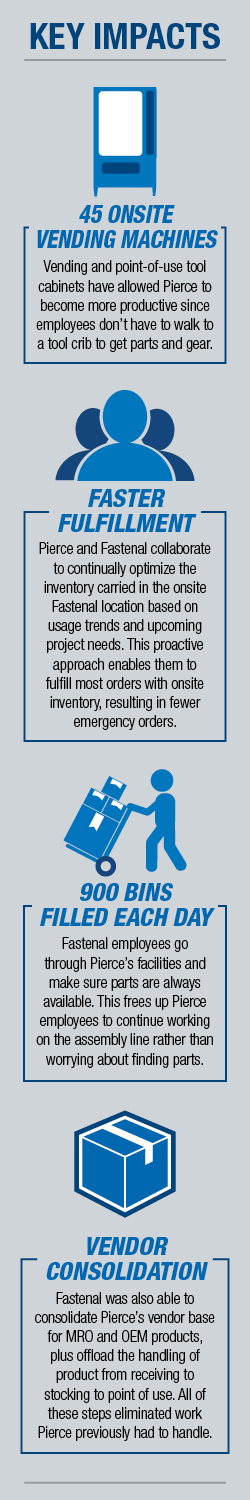

When the goal is to build vehicles that save lives, you need to use quality parts and stay focused on the job. That’s exactly what Pierce Manufacturing does as the nation’s largest producer of fire apparatuses. Each unit that rolls down the assembly line is fully customized with equipment that can pump thousands of gallons of water per minute or extend a ladder 107 feet up to a building. In business for more than a century, the company is no stranger to growing and changing with the times. And today, with their fire and rescue vehicles in such high demand, they look for opportunities to speed up production and improve their supply chain. “One of the complexities of our product is we build custom. We can’t drill down every different nut and bolt that might be used on the truck because they’re different configurations. There’s constant flux of how this product is built until the customer comes in to accept it,” said Terry Walsdorf, an engineer of fire suppression systems for Pierce.

|

Like what you're seeing here? Subscribe to the Blue Print for FREE and get the magazine sent right to your address.

TRUSTED COLLABORATORS Terry Wasldorf I Engineer, Fire Suppression Systems, Pierce Manufacturing

“We have a symbiotic relationship that developed over the years with Fastenal. They benefit from Pierce by having us as a customer onsite, and we benefit from having all of our needs for hardware, tools, and support for those services right at our doorstep.” Matt Leslie I Commodity Manager, Pierce Manufacturing

“We have Fastenal reps integrated right there on the manufacturing floor. If there’s something that our manufacturing folks are missing, the Fastenal reps are able to supply that at a moment’s notice, and that’s really key when we have to customize these vehicles to keep them moving through our facilities.” Troy Parkos I Regional Vice President, Fastenal

“Pierce makes an amazing product that’s in high demand. So their backlog is not days, it’s not weeks, it’s a year. They have the demand there. Their challenge is to get trucks to customers quicker. So we’re here to solve problems. It’s a lot more than just providing a product. It’s the value added behind the product.” |