How inventory management helps nuCamp get Lean

Updated May 5, 2023

By Curt Trnka | Blue Print Editorial Team

By Curt Trnka | Blue Print Editorial Team

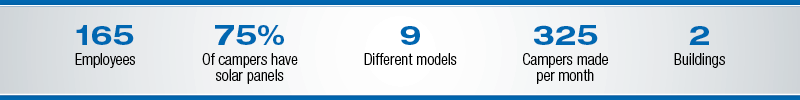

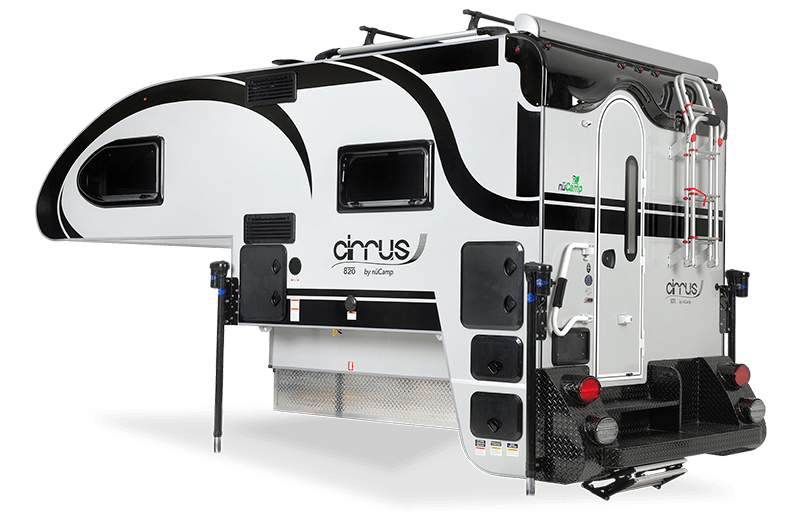

Based out of Ohio, nuCamp makes high-quality RVs.

|

CREATING SOMETHING SPECIAL

Kevin North had a really nice problem. It was such a nice problem, he didn’t have to look hard to find the silver lining. You see, North and his team at nuCamp were facing a large amount of unexpected demand. Yes, this was a great problem. Prior to the pandemic, nuCamp was on pace for good growth in 2020. Then COVID-19 drove demand up. Way up. Growth climbed above 20%, because people wanted to get away, get outdoors, and get off the grid. For many, “Let’s buy a camper!” became a way to reclaim some normalcy in their lives. And many found that the high-quality trailers nuCamp creates were just what they were looking for. “Here at nuCamp our four core values of Caring Genuinely, Service Over Self, Always Doing the Right Thing, and Work Hard, drive us to build the exceptional,” North said. “Our European designs infused with Amish craftsmanship enable us build remarkable RVs.”

|

WHAT IS FASTBIN?

Using RFID technology, the local Fastenal branch monitors nuCamp’s inventory remotely. Then, before it’s needed, they can replenish. Like what you're seeing here? Subscribe to the Blue Print for FREE and get the magazine sent right to your address.

ABOUT THE PARTNERSHIP

“With a company of our size, our product portfolio of over 3,000 parts was stretching our team members’ bandwidth. With Fastenal’s VMI system, our team could focus on their work without worrying about fasteners because Fastenal handles the management of our inventory.”

- Kevin North | Vendor Relations for nuCamp “They are a great company. They have a really cool product, they are eager, and they have great management there coming into a new era of wanting to get Lean.”

- Duane Shock | Lean Solutions Coordinator for Fastenal |