How a hydraulic torque wrench works

February 2, 2024

By Enerpac, for the Blue Print

By Enerpac, for the Blue Print

|

The working principle of a hydraulic torque wrench is the conversion of hydraulic pressure into torque. The resulting torque is applied to either tighten or loosen a fastener.

But how do they work and what happens inside the tool? In this article, we provide a simple overview of how both low-profile and square drive hydraulic torque wrenches work. How does a hydraulic torque wrench work?Setup and operation

The torque wrench pump needs to be set to the required pressure to make sure it delivers the correct torque. The operator usually refers to torque charts to find the correct pressure to provide the torque needed.

Next, a backup spanner is positioned on the nut on the opposite side of the flange to prevent it from turning during the tightening process. Now the torque wrench can be offered to the flange nut – making sure the reaction foot rests on a reaction point (commonly the adjacent nut). This is to counteract the force caused when operating the tool. The operator needs to ensure hands and fingers are away from any pinch points. The torque wrench pump can now be switched on. As hydraulic oil flows to the torque wrench, the piston advances inside the torque wrench, causing the hex ring to rotate around the nut. The piston is retracted, causing the ratchet to return to its starting position, and the process is repeated until the target pressure has been achieved. Important: The information provided is to offer a very basic overview only and is not intended as an operational guide. Hydraulic equipment should only be used by fully trained personnel and in accordance with the manufacturer’s operator’s manual. Does a square drive torque wrench work in the same way?The working principle of a square drive torque wrench is very similar. It also includes a piston that extends to move a ratchet. The main difference is that instead of a hexagonal ring, a square drive shaft is rotated, and this shaft fits into the required socket for the nut size.

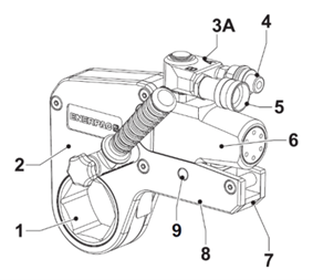

Low-profile torque wrench components

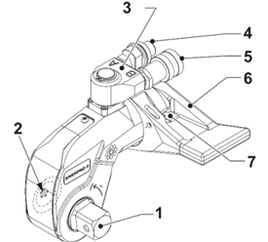

Square drive torque wrench components

What other equipment is used?

The process for loosening a nutWhat happens when a fastener needs loosening depends on the type of torque wrench.

When using a low-profile hydraulic torque wrench, the handle needs to be swapped to the opposite side of the wrench. The torque wrench can then be positioned back onto the nut, but in the reverse position. When using a square drive wrench, the square drive needs to switch to the other side of the body. The socket is then reconnected and positioned onto the flange nut in the reverse position. Note: More torque is often required to loosen a fastener than to tighten it. This is known as ‘breakout torque.’ It is therefore good practice for the operator to apply oil and leave this to penetrate before starting work. Content originally from Enerpac. Reused here with permission.

Vertical Divider

|

Want to save money?

Here's how you can improve quality and control costs just using your fasteners. Want to see more supplier content? Click here. |