Industry 4.0 and the future of supply chain

|

We all learned about the Industrial Revolution in history class – how steam-powered machines transformed manufacturing starting in the late 1700s. But the consensus view is that there have been multiple industrial revolutions since the Industrial Revolution. The second one (late 1800s–early 1900s) saw the rise of mass production sparked by electrical power and moving assembly lines. The third, which gained traction in the 1960s, has been powered by computing and process automation.

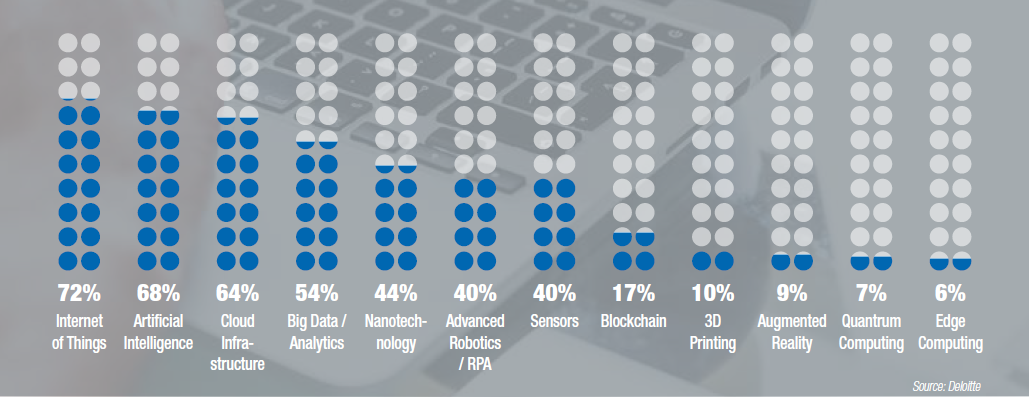

Many analysts believe we’re now living through a fourth industrial revolution, aka Industry 4.0. Some central themes are digitalization and connectivity – capturing, sharing, and applying data across the physical and digital realms. What technologies are driving Industry 4.0? Which will be the most impactful moving forward? According to a survey conducted by Deloitte, here’s what business leaders are thinking. Industry 4.0 technologies aren't in competition - they work in concert.

Things like IoT devices and sensors capture and share data … which is stored and organized in the cloud … where analytics and A.I. can be applied to improve business decisions. It’s all part of an interconnected, self-optimizing ecosystem. In manufacturing, everything begins with the supply chain, including the pathway from Industry 3.0 to Industry 4.0. Getting started is a collaborative effort. It requires supply chain partners committed to capturing relevant data and sharing it with your business. Not just month-end reports, but real-time data streams that can be integrated into your daily workflows and systems. A.I.-powered predictive and prescriptive analytics will play an increasingly important role. The progression will go from “what is happening now” to “what will happen next” and “what should happen next,” creating autonomous reactions to rapidly adapt toward the desired future state. What does "Industrial Supply 4.0" look like today? 1. Data capture (IoT connectivity) Mobile apps: Capturing and facing inventory-related data (product details, locations, activities); providing data-guided inventory replenishment suggestions. Automated supply: Using various technologies to monitor inventory, control access, and track how products are being used in the business. 2. Data analytics (descriptive, predictive, and prescriptive) Organizing captured data to visualize activities, patterns, and the current state. Creating simulated scenarios to predict and prescribe future states. 3. Systems integration EDI integration: automating the P2P cycle; feeding line-item details and usage data into the buyer’s ERP system. Integrating captured point-of-use data with supplier warehouse systems and other upstream systems for a more proactive supply chain. Integrating buyer-supplier demand forecasting systems to avoid gaps and risks. The next step: Artificial intelligence In a world of spiraling complexity and risk – as big data grows ever bigger – businesses are using A.I. to accelerate the path to insight and understanding. In the context of supply chain, it means synthesizing vast datasets and thousands of variables to predict demand, synchronize production, and optimize decisions surrounding procurement and logistics.

The vision is that A.I. can be used to produce instant, accurate answers and make autonomous decisions that optimize supply chain performance. How to build your 4.0 framework Implementing Industry 4.0 technologies doesn’t have to involve capital investment and IT resources. You can start by “plugging in” to Fastenal’s tech platform to collect, share, and visualize supply chain data.

Collaboration is the path forward Industry 4.0 is defined by technology, but the end goal is to improve human activities (logistics, engineering, production, etc.) and ultimately to improve the customer experience. It starts with relationships – a commitment from all stakeholders to develop the programs, make sure they work together, and adapt to change. A key step is moving beyond data segmentation (disconnected systems among various suppliers and locations) to embrace data sharing across the supply chain. In this environment, a competitive mindset is a roadblock; collaboration is the path forward. If you’re committed to Industry 4.0, you have a committed partner in Fastenal. We are heavily invested in technologies to capture and share supply chain data with your business. We are adopting A.I. in our own business, and we’ve established the clean, comprehensive data streams needed to make A.I. effective for our supply chain partners. Just as important, we’re invested in people to deploy, support, and optimize these solutions – a “team behind the machine” to help your business manage change and thrive in the fourth industrial revolution. In a survey of 400+ global manufacturing companies, 94% said that Industry 4.0 helped them keep their operations running during the pandemic, and 56% said their digital transformation was essential to their pandemic response. You may also like:

|

Want to learn more?

A great place to start is by reaching out to our team at [email protected]Let's talk about how we can work together to make industrial supplies part of your Industry 4.0 vision. Have you signed up? Subscribe to the Blue Print for FREE and get the magazine sent right to your address. Vertical Divider

|