Tips for picking out the drill bit you need

Updated May 5, 2023

By Dan Gernes | Sales Development Manager - Metalworking & Safety

By Dan Gernes | Sales Development Manager - Metalworking & Safety

|

Here’s a metric for you: cost per hole drilled. For work that requires lots of holes, it helps to know how to get the best cost per hole. Consider these areas while selecting a drill bit: geometry, material, and finish.

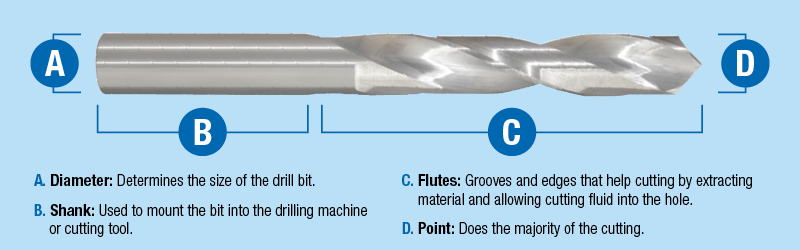

ANATOMY OF A DRILL BIT Understanding the distinguishing features of a drill bit is the first step toward identifying the proper products to use. A drill bit consists of four basic parts: the diameter, the shank, the flutes, and the point. DRILL BIT ANGLES EXPLAINED The 118° point angle is a smaller point angle and is ideal for drilling softer materials such as aluminum alloys. However, the 118° point may walk, requiring a center punch to spot drill the hole. The blunt point angle of a 135° split point drill bit produces smaller chips and can be used for harder and stronger materials. A split point is used to keep the bit centered without a pilot hole, preventing the point from walking. DIFFERENT MATERIALS & USES

THE IMPORTANCE OF FINISHES Finishes offer a layer of strength and protection to a drill bit’s surface. The two most common drill bit finishes Fastenal offers are black & gold and black oxide.

|

Customer Story: Drilling through concrete is no easy task. E-Z Drill works to make it, well, easier. Since 1987, they’ve been finding ways to make the tasks of drilling and doweling simpler, safer, and faster. How impressed has the E-Z Drill team been with Fastenal’s service? Check it out here!

Looking for Metalworking Tools? Contact Fastenal at: 844-365-8556 or [email protected] Like what you're seeing here? Subscribe to the Blue Print for FREE and get the magazine sent right to your address.

|