How to correct mistakes with adhesive anchors

January 10, 2024

By ITW Commercial Construction, for the Blue Print

By ITW Commercial Construction, for the Blue Print

Contractors occasionally install anchors improperly, and they must be replaced. One method is to core drill around the anchor in question and then install an adhesive anchor. Industry professionals often wonder if this a preferred or acceptable method of anchor replacement.

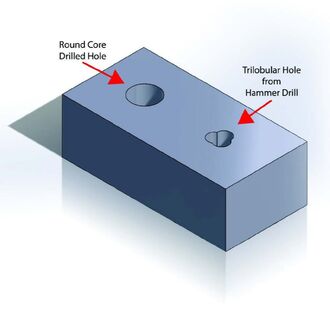

Maybe is the short answer. That’s because this method of replacing improperly installed anchors via core drilling stretches the scientific boundaries of adhesive anchoring. A core-drilled hole presents a very different surface to adhere to due to the smooth surface, which eliminates the nooks and crannies that occur naturally during the hammer drilling process. The hole itself is perfectly round instead of a trilobular hole, generated by hammer drilling (see illustration). This hole geometry change leaves the adhesive with significantly less mechanical and chemical bonding areas. Therefore, bond strengths are reduced in similar or comparable-sized holes. Hole integrity challengesAnother issue is that the new hole is generally oversized when core drilling around the improperly

installed anchor. An oversized hole can pose serious issues to an adhesive anchor solution since it presents a much larger area for an adhesive to shrink. For example, consider replacing a three-eighth’s-inch anchor. A contractor would drill a 1-inch hole around the anchor and use an adhesive with a 2% shrinkage. Under normal conditions, the recommended hole size for a three-eighth’s-inch anchor would be seven-sixteenths, or nearly 11 times less volume, for shrinkage to occur. The reduced bonding surface of the adhesive would further compound hole integrity. READ THIS: Five areas you can tackle in construction. Slurry complicates outcomeThe last area of consideration is that core-drilled holes are generally more difficult to clean. This is because of the slurry that remains in the hole after using water as a lubricant during the anchor replacement process.

A hammer-drilled hole is generally easier to clean. The dust is highly visible and moves easily by blowing because of the density and viscosity of the dust. On the other hand, the slurry can be nearly transparent on the walls of the hole, and is also difficult to remove since it can collect at the bottom of the hole as a thick paste. Workarounds reduce risksConsidering the concerns outlined above with using a core-drilled hole to repair an improperly installed anchor, one may assume this method of repair presents too many obstacles to effectively use this solution. That’s not necessarily the case.

First, the contractor could overcome the smoothness of the hole by simply going back and roughing it up with a hammer drill after the core drill. This process is simple and adds little complexity to this type of replacement. Next, it’s easy to overcome shrinkage by upsizing the anchor diameter for the proper sized hole. For example, use a seven-eighth’s-inch anchor instead of a three-eighth’s-inch anchor in a 1 inch diameter hole. If the anchor can’t be upsized easily, the manufacturer should be able to assist in recommending an adhesive for oversized holes. By taking into account the risks and knowing the recommended solutions, your repair will more often be stronger than the product it replaced. A core-drilled hole is a viable option in many situations. It should be used in consideration of the application and long-term performance required from the anchor. Content originally from ITW Commercial Construction. Reused here with permission.

Vertical Divider

|

|