A blueprint for a better operation (part 2)

June 5, 2023

By the Blue Print Editorial Team

By the Blue Print Editorial Team

|

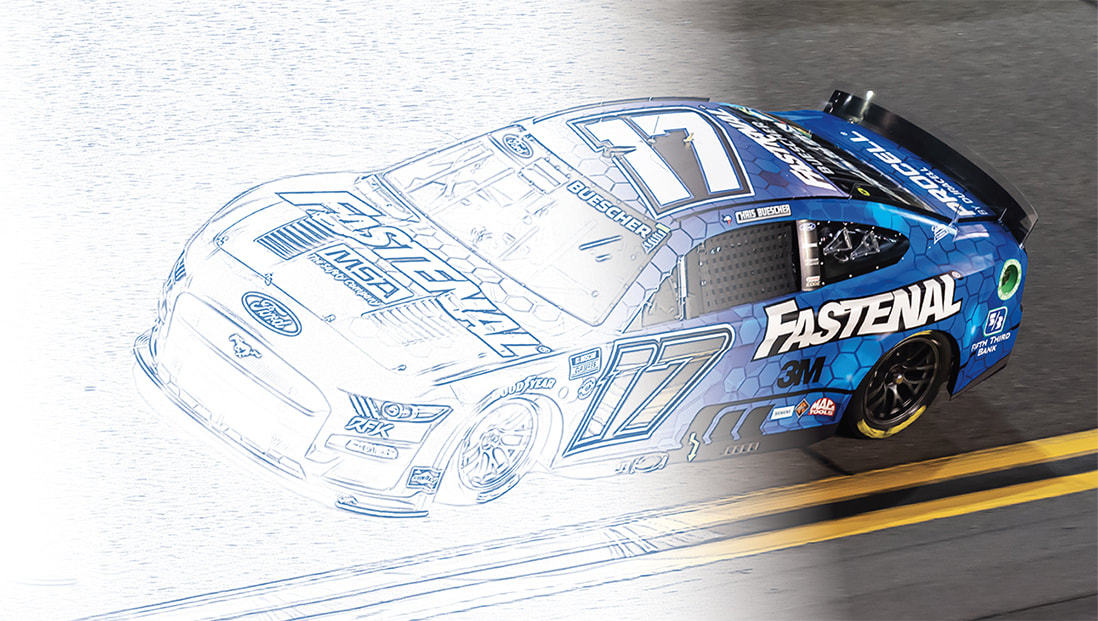

Built over the past decade, Fastenal and RFK Racing have a partnership that works. To see how it all runs, we talked with Chris Lewis, the purchasing manager for RFK. He shed some light on how inventory works for a NASCAR team.

Q: How have your purchasing habits shifted with the move to NextGen cars?A: The biggest change is going from raw material purchasing to single-source vendor parts. The parts come in already finished and ready to go on the car, instead of us manufacturing the part. Car parts are now coming to us from other vendors. Whereas in the past, we were able to get the raw materials in here and produce them on our timeline and through our processes. It changed how fast we can get them [parts] and how we can control the flow of production.

|

Fast Fact:"Being a NASCAR purchasing manager, we make thousands of

purchases every year, from race car parts to all kinds of different needs. Something interesting that Fastenal helps provide us with is that every year we go through almost 180,000 WypAll wipers. Fastenal is there to help provide those for us with their FASTBin solution." - Chris Lewis, Purchasing Manager for RFK Racing

Like what you're seeing here? Subscribe to the Blue Print for FREE and get the magazine sent right to your address.

|