How to pick the right leather for welding

UPDATED January 3, 2023

By Evan Hardin | Director of Safety, Health, & Environmental Sales

By Evan Hardin | Director of Safety, Health, & Environmental Sales

|

Can your PPE take the heat?

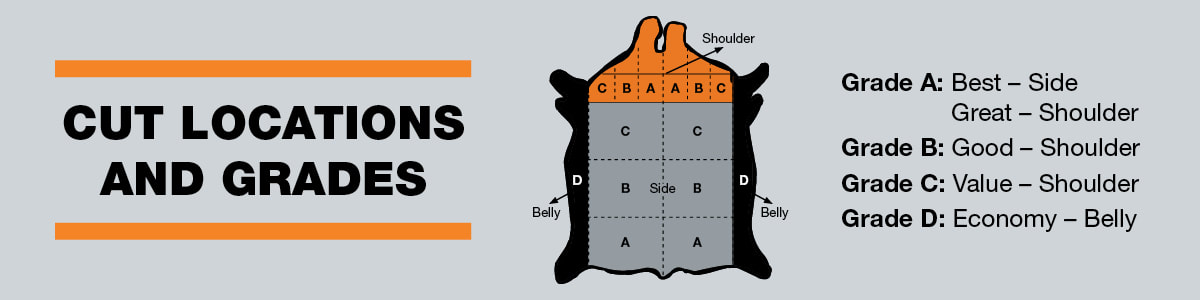

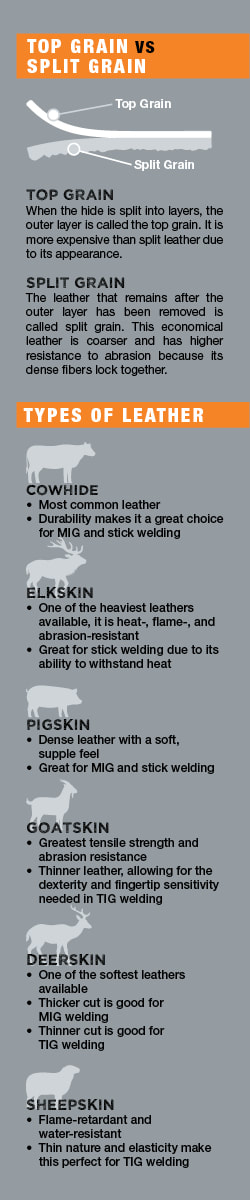

From welding to brazing and torching to cutting, leather is a commonly trusted material to protect workers. But why? The basics No two leathers are the same. Every source has its own unique properties. The four most common types of leathers used in welding and other heat- and fire-related work are cowhide, elkskin, pigskin, and goatskin. Each of these has specific cuts and grades to consider. Other types of leathers to consider include deerskin, kidskin, and sheepskin. There are two grain types of leather: top and split. Top grain refers to the outer layer of the hide, and it offers great durability and liquid resistance. Due to its appearance, top grain is more expensive. Split grain is the leather that remains when the outer layer is removed. This is a more economical leather, but it offers higher resistance to abrasion due to the denseness of its fibers. This makes split grain a great choice for gloves where wet and oily gripping is unavoidable. In some situations both cuts will be used, top grain on the inside, with the rougher split layer on the outside to provide grip. When referring to the cut of leather, where the cut is coming from matters.

Types of leather

Cowhide is the most common leather used in welding. This is due in part to its abundance, but also its durability. Its robust structure offers resistance to abrasion, sparks, and spatter, which makes it a perfect choice for tough jobs like MIG and stick welding. Naturally water- and dirt-resistant, cowhide is easy to care for. Slightly more durable than elkskin, it’s not quite as soft. However, cowhide is preferred for comfort over other non-leather materials, allowing it to be worn for longer periods. The combination of durability and abundance makes cowhide leather both a great choice and a great value. Of the soft leathers available, elkskin is one of the thickest. A very durable leather, it is the most heat-, flame- and abrasion-resistant and won’t harden as fast as other options. It stays soft, even in hot and wet conditions, and conforms to your hand offering great movement and flexibility for the wearer. Elkskin’s ability to withstand heat makes it perfect for stick welding. Pigskin is a dense leather, which means it’s not as flexible as other leathers on the market. However, small pores in the leather allow the wearer’s skin to breathe and also make pigskin gloves one of the most durable options. Pigskin leather has a supple feel, and it stays soft, even after getting wet. However, pigskin leather is not recommended for use in jobs where moisture levels are usually high. Pigskin leather is great for MIG and stick welders, where durability is a must. Goatskin is good if your job requires high tensile strength and flexibility. A thin leather, goatskin is soft and pliable but still offers great protection against cuts and abrasion. The higher lanolin levels in the skin offer a barrier against moisture, and the thin nature of the material offers great fingertip control. Its strength and durability make it great for MIG welding, and when coupled with the dexterity, it’s a perfect choice for TIG welding. The highest quality leathers for fingertip sensitivity come from kidskin, a very soft and lightweight leather from young goats that also provides the durability and abrasion resistance required. Deerskin gains attributes from the fact that deer spend their time in thorny, rough conditions, so their skin is naturally tough. This gives deerskin leather the ability to hold up against cuts and abrasion. Even though it’s tough, deerskin leather is lightweight and spongy, which makes it one of the softest and warmest leathers available. It is also one of the only leathers that can spring back to its original shape and softness after getting wet. Thicker cuts of deerskin leather are a good option for MIG welding, while thinner cuts are a good choice for TIG. Sheepskin, unlike other leathers, is tanned with the wool intact. The wool provides insulation and is also resistant to flame and static electricity. Sheepskin is thin and elastic, allowing for flexibility and sensitivity, which makes it perfect for TIG welding applications. Its natural lanolin content helps heal sensitive and inflamed skin, and the fibers draw perspiration away from the skin. Selecting gloves When faced with the decision of which leather to choose, remember to consider the applications where they will be used.

Are you using the right extension cord? Vertical Divider

|

Like what you're seeing here? Subscribe to the Blue Print for FREE and get the magazine sent right to your address.

|