How vending reduced walking time for Sundowner Trailers

Updated May 5, 2023

By Blue Print Editorial Team

By Blue Print Editorial Team

Coleman, Oklahoma

|

SAFELY MOVING AROUND

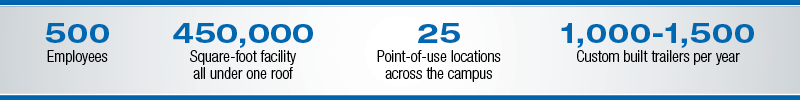

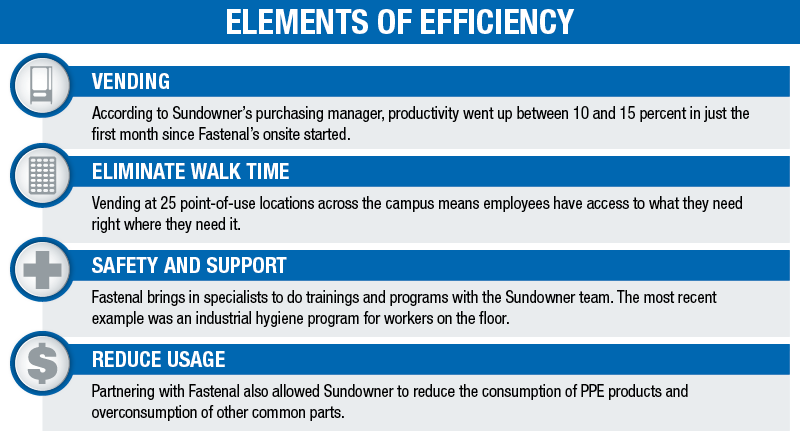

When the job is hauling a prized horse or a vintage Mustang, the mode of transportation matters. Sundowner Trailers understands this and has used 40 years of experience to become an industry leader. Customers rely on them to build quality devices to haul precious cargo. Something that sets Sundowner apart in the world of custom-built trailers is their response time. They know that timeliness is key. Speed lets them get – and keep – more business. And with a facility that produces more than 1,000 trailers per year, Sundowner is always looking for ways to get faster. Because they are a single-location manufacturer, hundreds of employees are spread across one campus, most in one building, all working to build each trailer to the Sundowner standards with the right tools and parts in the most effective and efficient way. “One of the biggest values that we take a lot of pride in here at Sundowner is being able to produce a product that is done in-house,” said Mike Mason, Sundowner’s purchasing manager. “And what I mean by in-house is, from start to finish, that trailer is done here on site in Coleman, Oklahoma, has been since 1976, and we take a lot of pride in the product that we produce.”

|

Like what you're seeing here? Subscribe to the Blue Print for FREE and get the magazine sent right to your address.

THE TEAM'S PERSPECTIVE Mike Mason | Purchasing Manager, Sundowner Trailers

“As far as how the Fastenal crew interacts with the crew here at Sundowner, it’s been a tremendous asset, always willing to go the extra mile, always willing to do whatever it takes to get product here, which makes my job a lot easier.” Justin Walker | General Manager, Sundowner Trailers

“We’re a large company. We use a lot of small parts. I was really worried about the transition because there are hundreds and hundreds of parts that we did not deal with necessarily. And anytime you have a parts outage it can really cripple your production flow, which costs money. I was very pleased with the way Fastenal planned and prepared, and our transition could not have been smoother.” Kyle Hughey | District Manager, Fastenal

“The benefit of a Fastenal Onsite is that it’s the costumer’s solution and not a standard cookie-cutter solution. So, what worked best for Sundowner and what we’ve been able to implement is we manage a centralized warehouse – a tool crib, so to speak – but we’ve got 25 different point-of-use locations scattered across their campus and we manage over 800 SKUs. We were able to bring in four Fastenal employees that are at no cost to Sundowner, and they’re now part of the Sundowner culture and part of the Sundowner family.” |