Sarasota County Schools find partner to reduce item consumption by 30%

Updated May 5, 2023

By Mark McGroarty | Blue Print Editorial Team

By Mark McGroarty | Blue Print Editorial Team

The school district relies on Fastenal to strengthen their supply chain.

|

STUDENTS FIRST

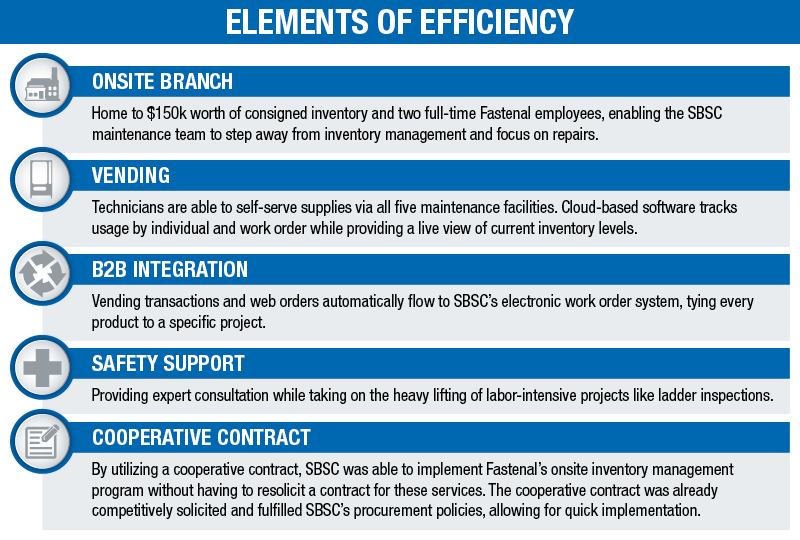

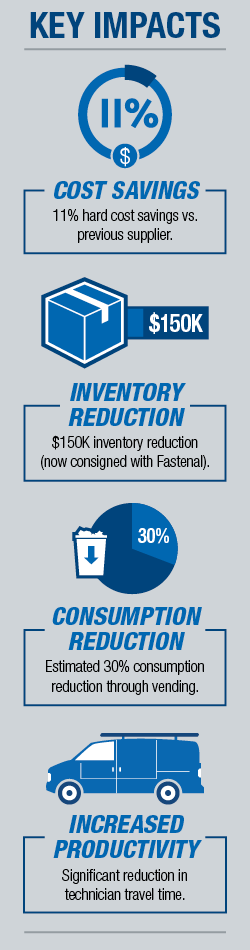

Every day, the School Board of Sarasota County (SBSC) facilities maintenance department faces a twofold mission: (1) maintain a safe, productive environment for teachers and students across the county; and (2) do the job as efficiently and effectively as possible, keeping finite resources focused on the #1 priority – students learning. With more than 50 educational sites and five maintenance facilities spread out over multiple geographic zones, this is no small feat. It requires daily communication with principals and custodians, careful planning to optimize labor resources, and a well-orchestrated supply chain to make sure technicians have the right parts when and where they need them for each job. “Something we follow very closely is the cost per square foot for maintenance and custodial,” said Jody Dumas, executive director of facilities planning and construction. “The lower we can drive those numbers, the more money is available for students in the classroom. So I’m very proud when we’re able to operate effectively and efficiently.”

|

Like what you're seeing here? Subscribe to the Blue Print for FREE and get the magazine sent right to your address.

WHY FASTENAL Jody Dumas | Executive Director of Facilities Planning and Construction

Responsibilities: maintenance and custodial operations along with long-range planning and construction “For us, it’s a hands-off approach for parts and supplies. And that’s really what I wanted to have in the district – to have Fastenal come in, be integrated with our entire operation, and be able to get parts where we need them, when we need them, and how we need them. I’m a pretty demanding customer, so I asked that of them, and they’ve done a great job of doing that for us.” "At the end of the day, what’s important for us is making sure our customers and students are taken care of. But another important piece is taxpayer money. Community members are always asking us to run the school district like a business. Well, we are running it like a business. We focus on what we do best, and we bring in partners like Fastenal to do what they do best – efficiently distributing parts and supplies so we can make repairs at a very low cost." Steve Clark | Facility Manager

Responsibilities: Zone 2 maintenance and custodial operations along with OSHA compliance for the department “I’m at an on-the ground level at the zone, and I see the key things that Fastenal brings to us. Obviously cutting time and guys getting their parts is critical, and so is inventory tracking and control. But there are a lot of other support pieces Fastenal offers to us that I personally didn’t know about until we had a solid handshake partnership. Now they’re coming to us with ‘we can do this and that for you,’ sometimes at little to no cost. All of those things just help us to better serve our customers.” |