Gorman-Rupp turns to automated bins to collect usage data

Updated May 5, 2023

By Blue Print Editorial Team

By Blue Print Editorial Team

The Fastenal team works during the implementation at Gorman-Rupp's location in Mansfield, Ohio.

|

ALWAYS PRIMED FOR MORE

When the U.S. military needs a pump to handle tough jobs, they trust Gorman-Rupp. With almost nine decades of experience engineering and manufacturing pumps, they are certainly qualified for the job. Their employees are proud to say that many of their innovations are now industry standards. With a successful history, a state-of-the-art facility, and an experienced staff of engineers, Gorman-Rupp is always looking for the next way to move the company forward. “We want to set our employees up for success,” said John Stevens, manufacturing manager at Gorman-Rupp. “Anything we can do to make the job better helps the team, helps the product, and helps the customer. We want that.”

|

Like what you're seeing here? Subscribe to the Blue Print for FREE and get the magazine sent right to your address.

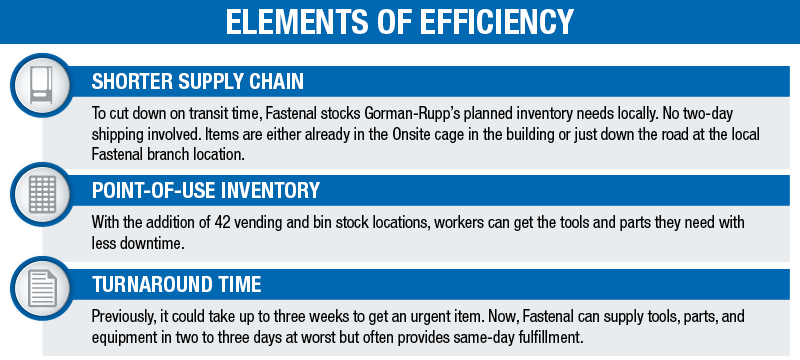

ABOUT THE PARTNERSHIP

Gorman-Rupp's Take John Stevens | Manufacturing Manager “It was common [for workers] to be about 80 steps away from the resources. It could take up to 15 minutes to get parts and get back to their work centers. We have significantly improved these metrics, and improved overall morale due to our Fastenal partnership.” “Gorman-Rupp wants to get better via continuous improvement for the sake of our employees and customers, and Fastenal is helping us get there.” Fastenal's Take Gene Humes | Director of Lean Solutions “We invested in this partnership by going on-site in their business and dedicating a tenured employee to help manage their business. This opened the door to a new level of partnership with them where we could have the trust to continue bringing value to their business. There is a lot of vending in there, technology has been always a piece of it but our investment with the right person in the on-site role has brought the greatest single value.” What Industries Does Gorman-Rupp Serve?

How Fastenal Helps With OEM

How Fastenal Helps with MRO

Additional Industrial Services: Fastenal’s implementation team created a regrind system for round tooling. Workers now have a regrind center with a collection area for scrap metal. When full, Fastenal recycles the metal via GreenTech and gives that money back to Gorman-Rupp. |